[Courtesy of ETRI]

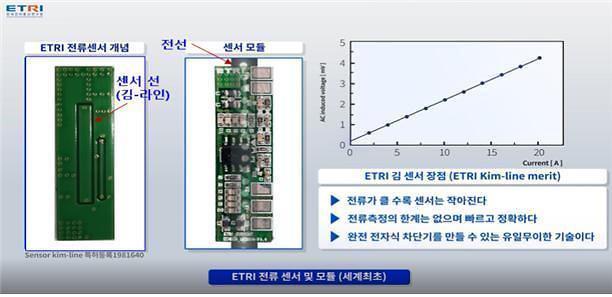

SEOUL -- Researchers have developed the world's first non-coil type current sensor module that uses electromagnetic waves to detect and cut off overcurrent occurring in high-voltage infrastructure faster than conventional sensors. The new sensor is ideal for protecting expensive automated equipment at a smart factory or the battery of an electric vehicle.

Current sensor modules with bimetal switches are installed inside an overcurrent protector device attached to a power line. Sensors monitor abnormal heat or magnetic fields to detect overcurrent. However, a bimetal sensor has an error range of about 500 percent and is relatively slow as a bimetallic strip would have to be affected by heat to physically bend and turn on the switch of the overcurrent protector.

The Electronics and Telecommunications Research Institute (ETRI), a state-funded research institute, said in a statement on June 23 that its technology was transferred to a domestic company for commercialization. The institute predicts the new sensor will prevent overcurrent accidents at high voltage facilities such as smart factories and electric vehicles powered by large-capacity batteries.

Because it is only a few millimeters wide, the new sensor requires very little manufacturing costs. Researchers said the new sensor can detect an overcurrent situation about five times faster than conventional products. "Thanks to the development of the ultra-fast sensor, we were able to develop e a full electronic power breaker," ETRI said, adding the power breaker based on the non-coil sensor can cut off electricity in just four milliseconds.