[Courtesy of KIMM]

Wearable robots come in various sizes and types. The most common one is an exoskeleton type made of metal and polymer materials. An exoskeleton suit features actuators and a power source designed to boost the strength of wearers. Exoskeleton-type wearable robots have been researched for industrial use. Fabric types are researched mainly in the military and medical sectors.

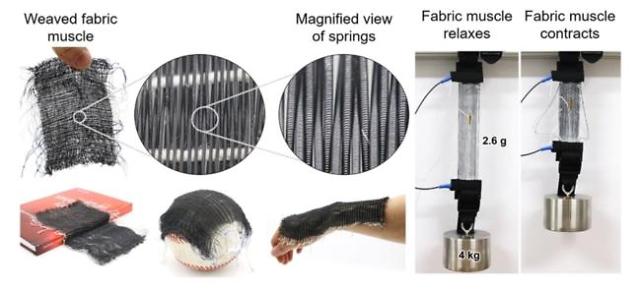

The Korea Institute of Machinery & Materials (KIMM) said in a statement on April 14 that its research team led by Park Cheol-hoon has developed a fabric muscle technology capable of providing strength to desired body parts. The new robot muscle is light and comfortable. It offers strength only when required by wearers.

Researchers have tested the new technology using a palm-sized fabric muscle made of shape-memory-alloy materials, the institute said. When an electric current is supplied, a 6.6-gram fabric patch created enough force to lift 10 kilograms (22 pounds).

The fabric muscle can be attached to arms and legs, allowing the wearer to perform basic movements such as standing up and lifting a heavy object, the institute said, adding such tasks can be carried out with only 50 percent of the wearer's strength.

KIMM would use its new technology to develop a suit-type wearable robot that can be applied to delivery workers and care workers. Patients can also use it for rehabilitation training.